Master Bond’s Epoxy Compatibility with STERIS’s Vaporized Hydrogen Peroxide Sterilization Process

As medical devices have evolved through technological advancements, they have become more complex in both their design and materials of construction. Medical-grade biocompatible epoxies are widely used in reusable medical devices. Choosing an epoxy that maintains its performance characteristics when subjected to repeated sterilization throughout the reusable medical device’s lifespan is a known challenge for medical device manufacturers. This study evaluated the material compatibility of seven cured two-part and one-part epoxies used in medical devices following exposure to 100 cycles in a low-temperature vaporized hydrogen peroxide sterilizer.

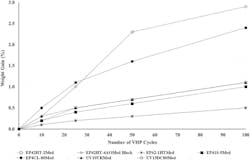

Six of the seven epoxies tested were found to be compatible with vaporized hydrogen peroxide sterilization based on qualitative, hardness, and weight measurements conducted post-exposure to 100 VHP cycles. The epoxies deemed to be compatible displayed no visual signs of physical defects, minimal reduction in hardness (≤2%), and total weight gain (≤2.9%). This study highlights the importance of conducting material compatibility studies, and continued collaborations (among medical device manufacturers, sterilizer manufacturers, and epoxy manufacturers) during the early stages of medical device development to ensure a successful reusable medical device that will withstand repeated sterilization

Key Findings from the Study about Master Bond Medical Adhesive Systems

The Master Bond EP42HT-2Med, EP42HT-4AOMed Black, EP62-1HTMed, EP41S-5Med, EP4CL-80Med, and UV10TKMed epoxies are compatible with low-temperature vaporized hydrogen peroxide, as they maintained their surface texture, exhibited less than 2% change in hardness, and displayed less than a 2.5% weight gain post-exposure to 100 VHP cycles.

To read the experiment and results in its entirety please go to https://www.tandfonline.com/doi/full/10.1080/25740881.2024.2376209 or contact technical support to discuss your application.

TECH SUPPORT

Email: [email protected]

Web: https://www.masterbond.com/contact

Tel: +1-201-343-8983

Note to Editors:

Check out new videos on our YouTube channel: https://www.youtube.com/user/MasterBondVideo

You can embed any of our videos on your website.